A detail often neglected by purchasers is the heat sink design of LED-lamps. However, without proper heat sink design common LEDs are likely to overheat soon which may result in an early brightness decay of the lamp. FecosLED has developed new heat sink designs for LED-downlights in order to ensure proper heat dissipation.

Heat sink designs encompass a broad variety of different types such as spinning heat sinks, pin or fin heat sinks, radiator or convector heat sinks, pure aluminium or die cast heat sinks, anodized heat sinks and more. Additionally, heat sink fins or pins can be designed and installed in different ways. To choose the right type of heat sink depends on the type and design of the LED-lamp housing itself.

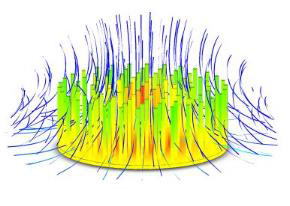

LED downlights can develop comparatively high temperatures within a small lamp housing. Therefore it is of high importance not only to choose the right heat sink design, but also to install it properly onto the lamp housing in order to avoid air gaps. In the case of LED-dowlights, it is furthermore indispensable to examine, if a radiator or convector heat sink should be used. Moreover, the thickness of the layers has to be checked and an adequate size of the heat sink to be chosen.

In this month, FecosLED has undertaken extensive measurements regarding LED-heat sinks for LED-downlights. Particularly the thermal conductivity and convection coefficient of the fins was measured in order to ensure thermal efficiency. The results have been partially surprising and once again showed, that an intelligent heat sink design outpaces increased use of raw material by far. Based on these measurements, FecosLED has now released new heat sink types for LED-downlights with high thermal conductivity and optically attractive appearance. md