A frequently arising question amongst our customers is the nature of plastic material used in lamp shades like ceiling lamps. In this context the key concern of many purchasers is the material quality and its effect on the lighting as well as simple cost questions.

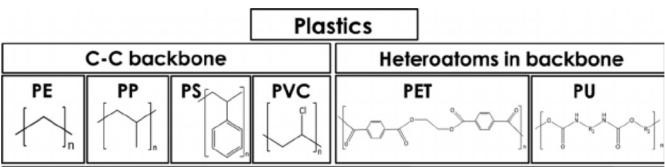

The most common used plastic materials in lamp shades are PMMA (or simply acrylic), PC (Polycarbonate), Polyethylene terephthalate (PET), high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP). With so many different types of materials available, it is necessary to work out their key features.

The key advantage of PMMA is certainly its high transmission rate allowing at least 92% of light to pass through, which is more than other plastics or even transparent glass. PMMA also provides good resistance to UV light and environmental wear and does not become yellow as PC does under the influence of heat.

PC on the other hand has higher impact-resistance which makes it suitable for applications where durability is necessary. Last but not least this resistance against impacts also can prevent damage during transportation. PC is more expensive than PMMA, although also factors like the thickness of the lamp shade define the price.

PET (polyethylene terephthalate) lamp shades are produced to a fewer extent and do neither have the impact resistance of PC nor the transparency rate of PMMA. The key advantages of PET are its lower price and the eco-friendly recyclability which recently is a huge trend in the LED lighting industry.

Polypropylene (PP) has the lowest transparency rate and impact resistance of all mentioned plastic materials and is therefore less frequently found in LED lamp shades. However, PP has the lowest price of all mentioned plastic materials and thus offers cost-efficenct solutions.