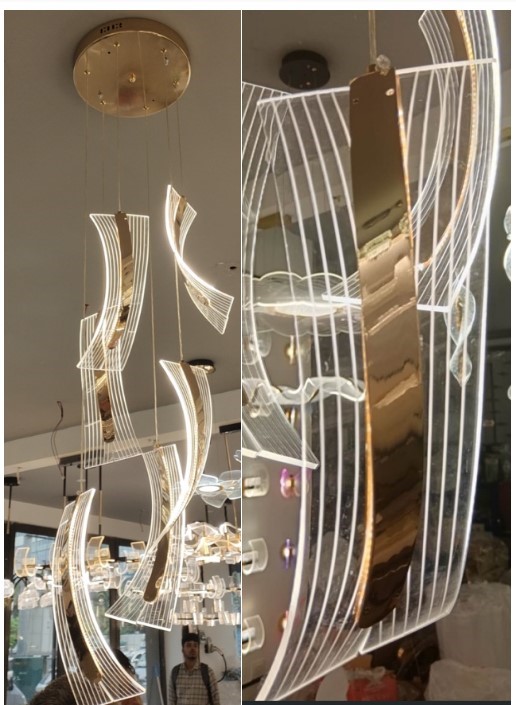

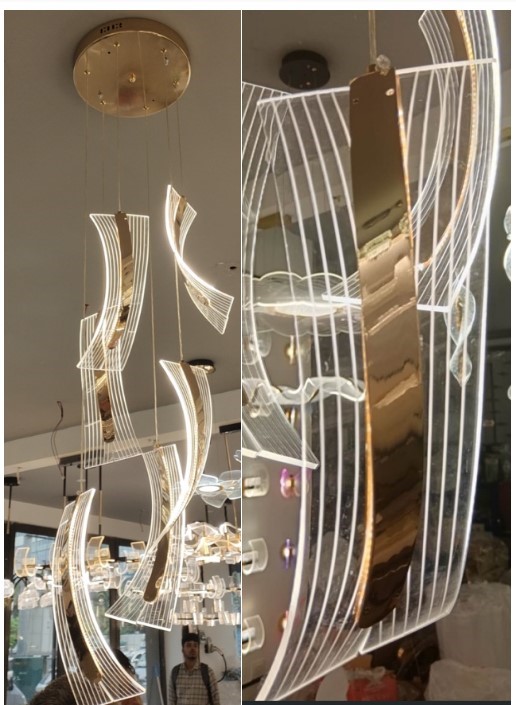

Following our participation in the International Lighting Exhibition in Guangzhou, many questions of our clients emereged regarding the topic acrylic LED lamps. Naturally, the most frequently asked questions referred to the quality of the material. In this article we want to explain some of the key quality features.

First of all it has to be stated that the acrylic LGPs (Light Guiding Plates) come with three different quality levels, A-, B- and C-level. The level itself is defined by the purity of the acrylic. While A-level acrylic mounts up to 100% of purity, B-class level may only have a purity of about 50% and C-class acryilic may range at levels of about 20% only. These different purity rates are created through the admixture of cheaper non-acrylic materials or acrylic waste material. On the market there are even complete fake “acrylic lamps” offered that are made entirely of cheaper PE material.

In this context, the key question is how different purity levels effect the function of the lamp. B- and C-class level acrylic will have strong yellowiing effects within time. In the other side, A-class level acrylic can withstand the yellowing effect easily in a time period over 3 years, even if the lamps are being operated over a long period of time. Another important advantage of A-class level acrylic is its ability to guide the light through the PMMA in an even and bright way which makes the lamps looking much more attractive. A final advantage of A-level acrylic lies in its ability to withstand heat Cheaper materials will show cracks after short time, especially if operated for many hours. After the fair, many of our clients have visited our showroom in which the lamps are being operated at least 11 hours per day. As they could see, also with such long operating times, our acrylic lamps remain steady in their quality.

As with other LED lamps, the quality of the power supply and LEDs is obviously another important quality feature. Many LED acrylic lamps are being offered with insufficient Wattages to save cost on the electronic parts. As a result, their brightness is insufficient as well and the lamps lose their value as a decorative item.

A final feature is the overall thicknes of the lamp material, namely the acrylic LGPs and the metal parts. Cheaper acrylic material that is additonally thinner than usual only enhances the negative effects as described above. The same applies for thin metal parts that particularly have a negative effect on heat dissipation and therefor result in earlier brightness decay.